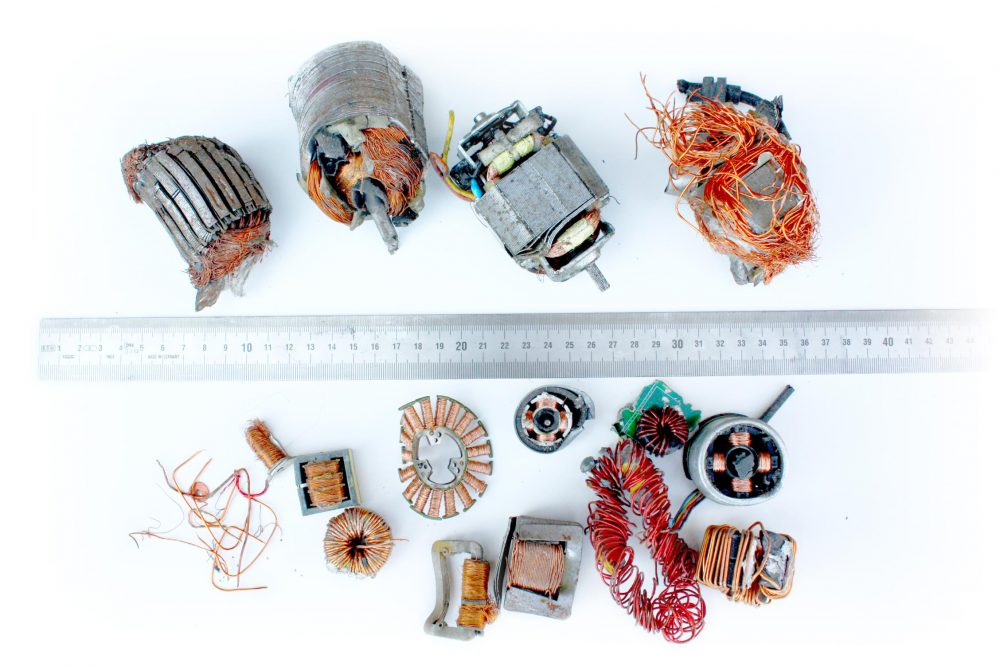

Recovery Rate

The recovery rate can reach 99.3% by using the TA-PO 1000.

Uptime

The motto is quality and simplicity. One of the building criteria of the TA-PO 1000 was the uptime. Due to innovative design on various components, maintenance is kept to a minimum and can be done in a short period of time.

Bewezen resultaat

The machine has proved itself in practice. Due to the stable and high-quality process maintenance time is 0.4% and maintenance cost of 2.2% of the investment on a yearly basis. This leads to low operational costs.

Conveyer belt

From a vibrating table via a chute, the material is evenly transferred to the conveyer belt. The conveyer belt ensures that the particles reach the set speed.

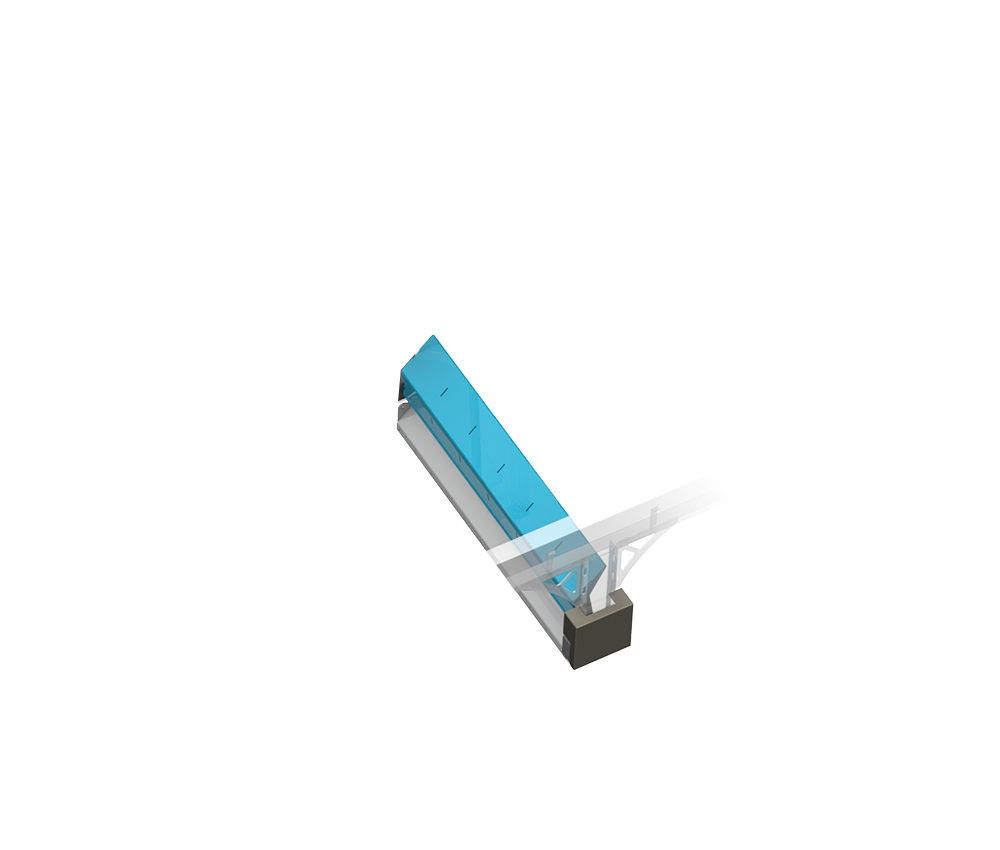

Magnet

The specially developed magnet ensures a stable magnetic field. In this field the partially magnetic parts are attracted less than the magnetic parts.The magnetic field can be adjusted to your specific requirements.

Splitter

The splitter can finetune the separation between magnetic parts with a short discharge curve and partially magnetic parts with a longer discharge curve.

Separate like a boss

Get the best result with help of the TA-PO 1000.

Bring your own material for a test run

Run a test with your own scrap material and convince yourself that more copper can be extracted from your ferrous scrap.

- TypeTA-PO 1000

- Weightca. 6800 kg

- Power consumption10 kW

- Voltage3x400V

- Frequency50Hz

- Noise level< 70 dB(A)

- Temperature range-10ºC - 40ºC

- Capacity fraction size10 t/m 200 mm

See more details in the brochure of the TA-PO 1000.